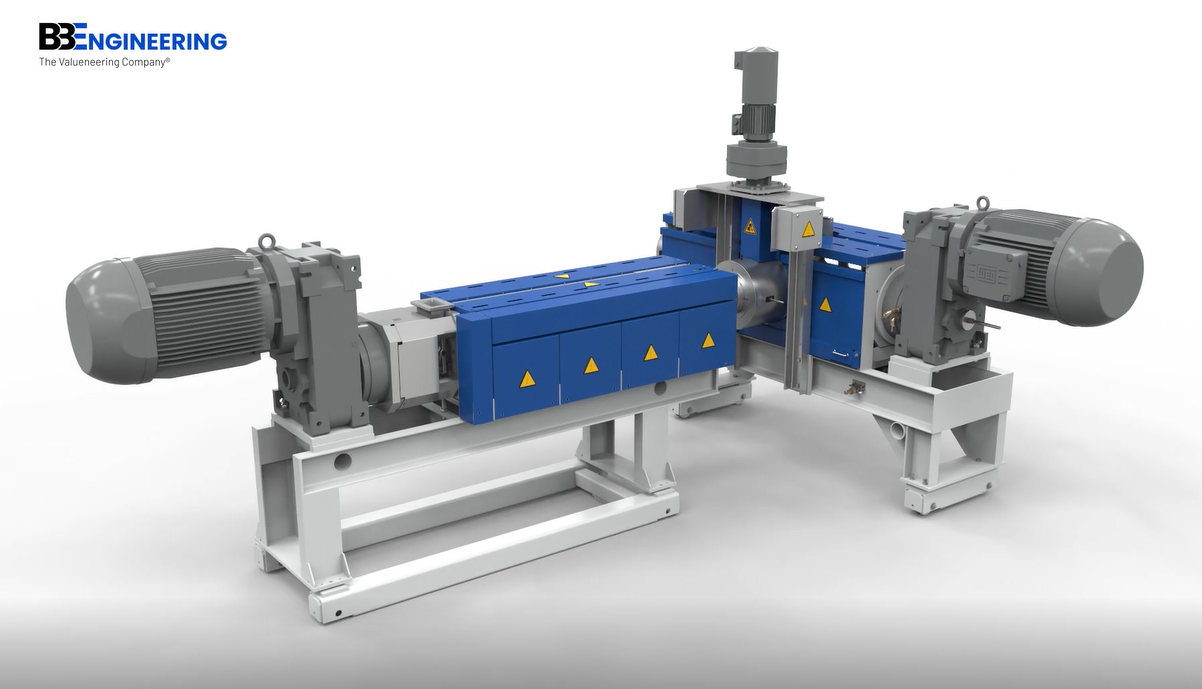

Complex melt mixing and melt modification for high quality products

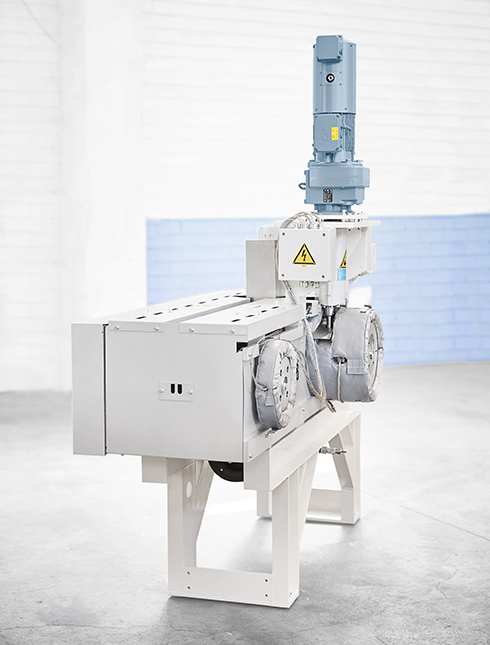

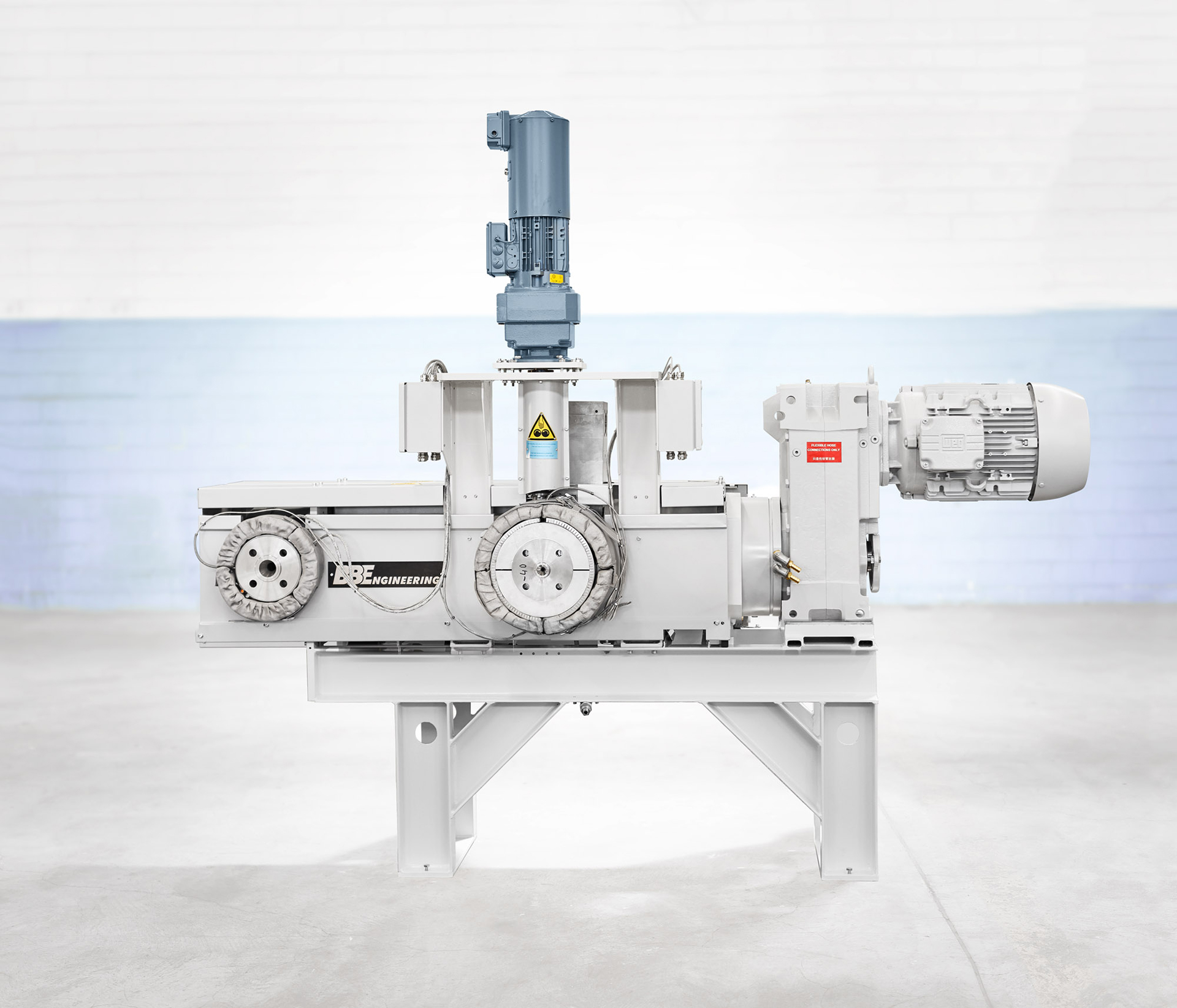

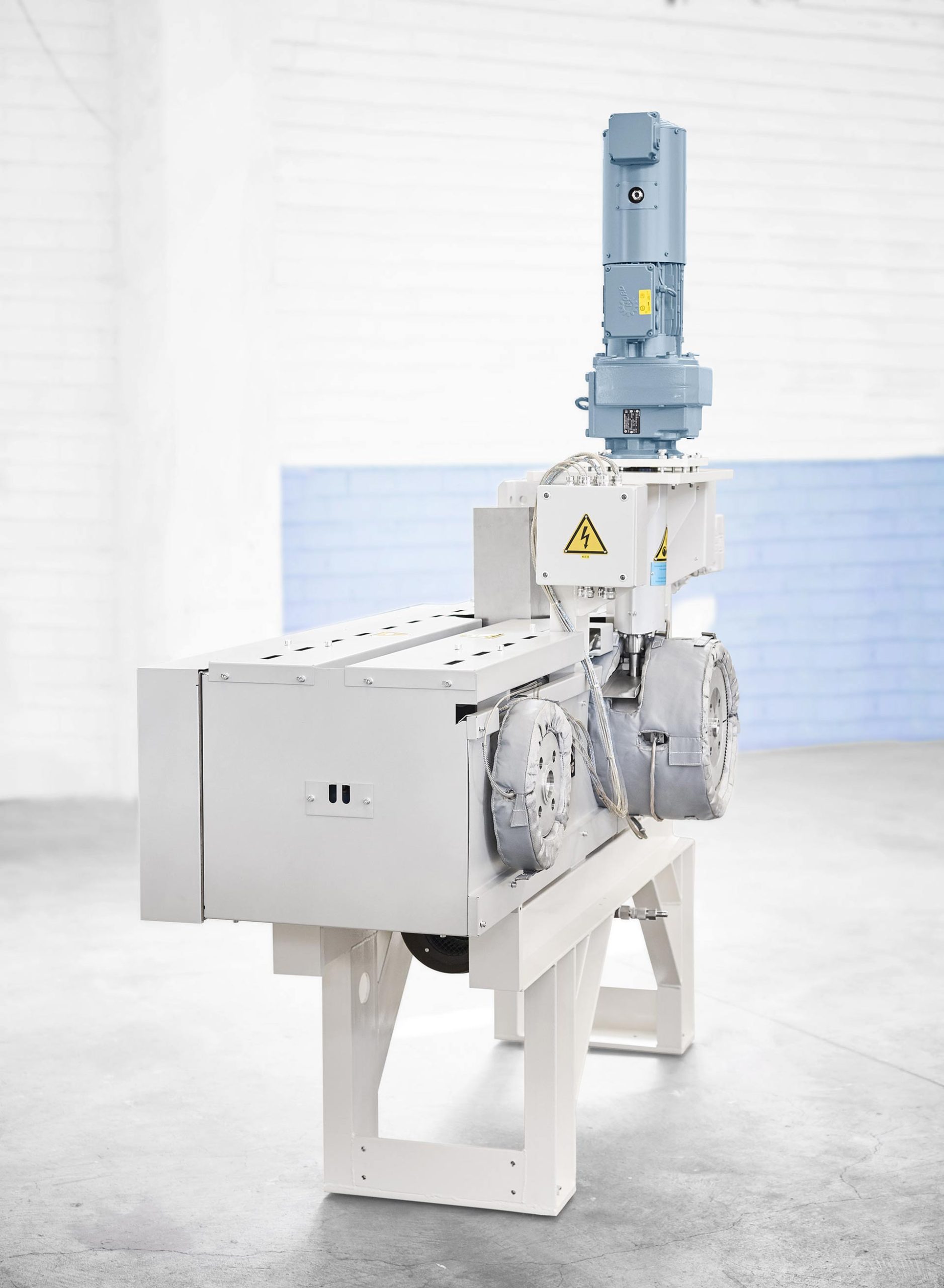

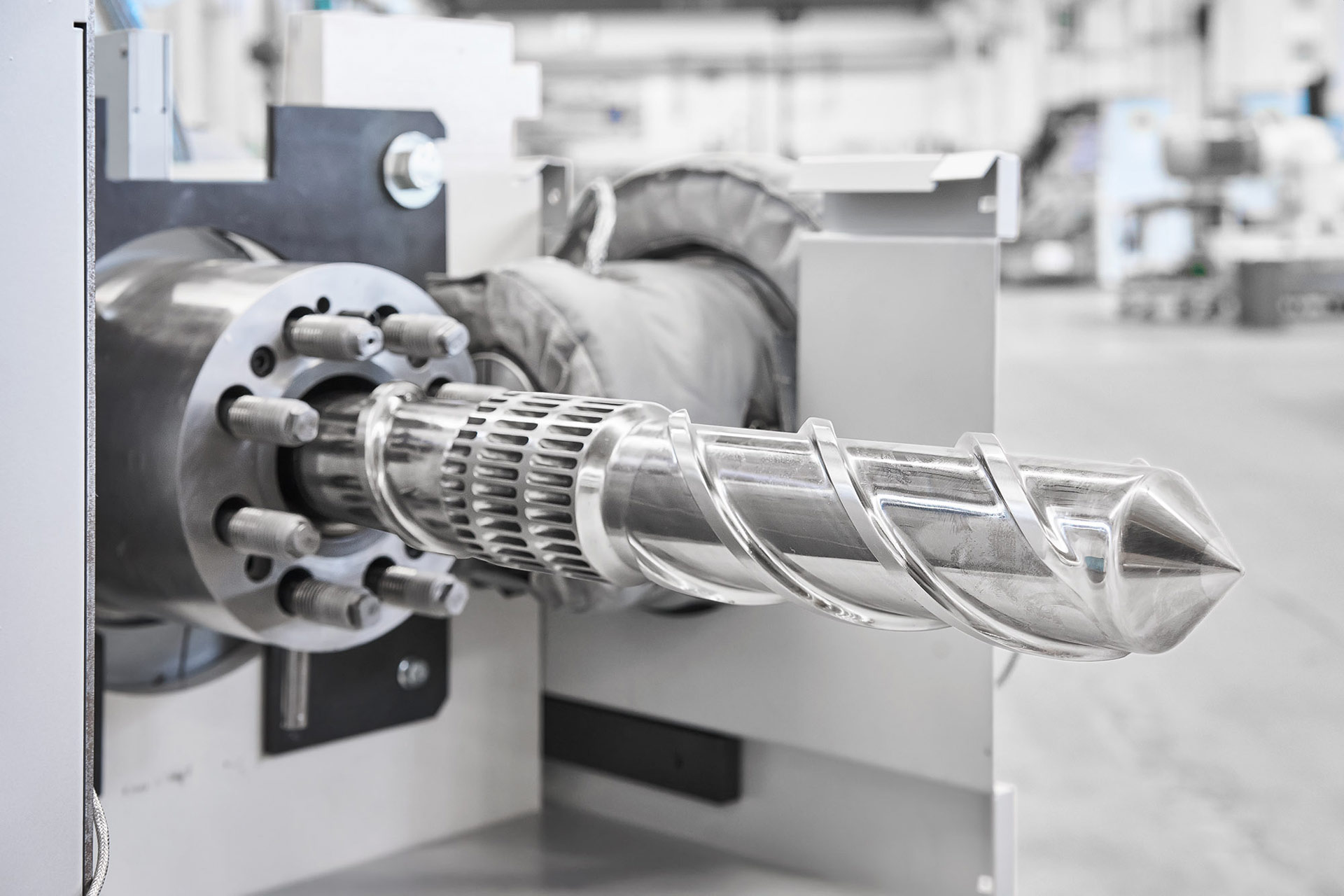

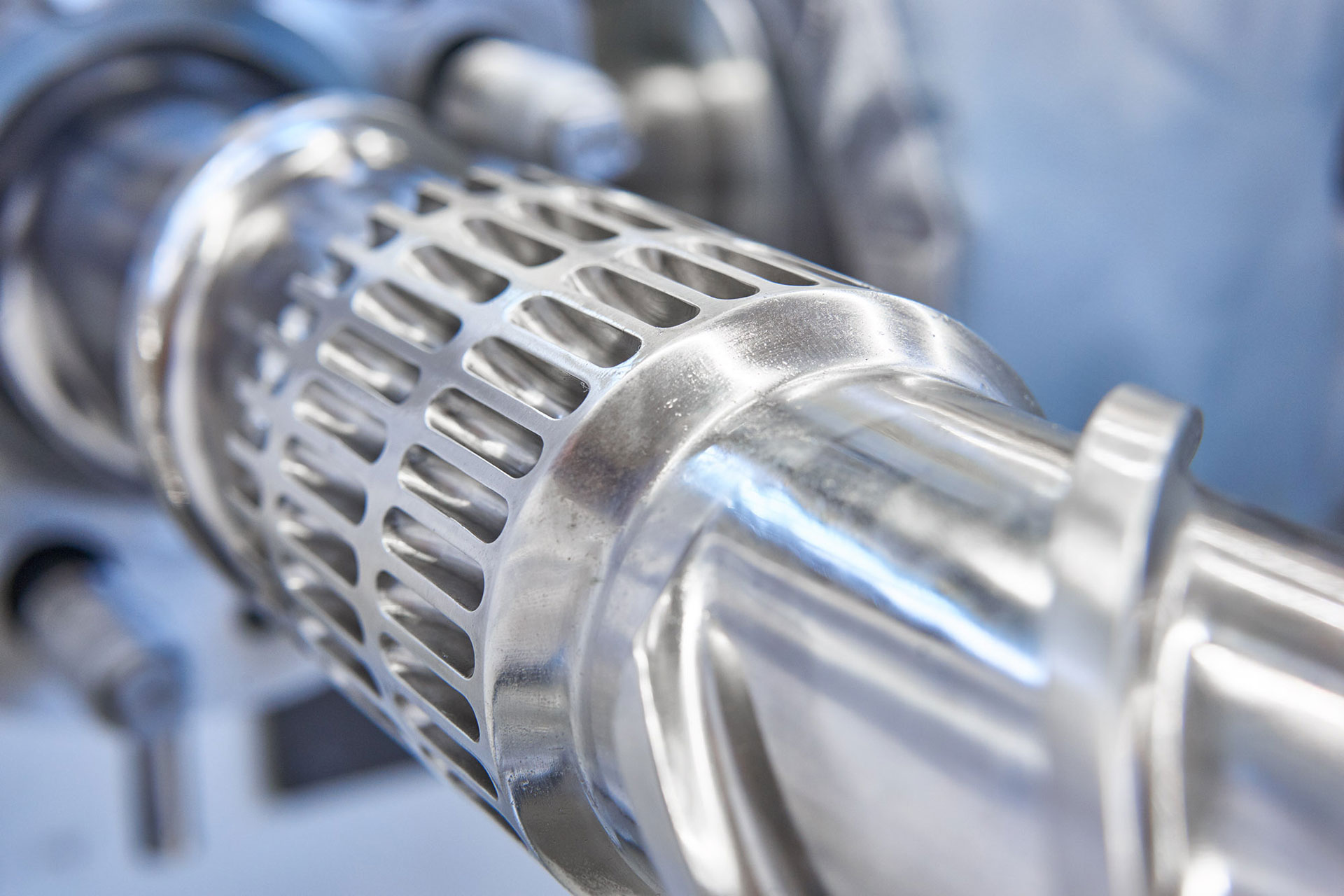

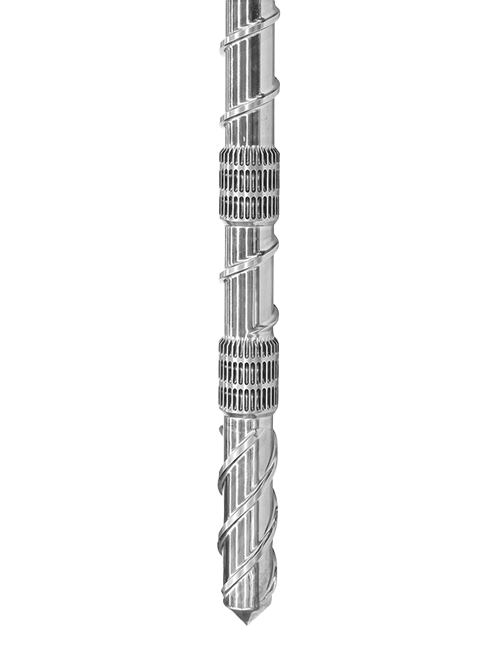

The 3DD Mixer is an add-on component for the flexiblisation of condensation plants, as well as extrusion systems, allowing the addition of colours and additives into the melt pass at various points of the polymer system. Our unique 3DD (3 Dimensional Dynamic) mixing principle provides excellent distributive and dispersive blending, hence fulfills a variety of mixing and thereby ensures your products’ quality. Primary applications are e.g. blending dyes, stabilizers, fillers, master batches, and liquid dyes.